DRI recuprator

Recuperator

Recuperator is one of the key equipments of recovery units

Ensuring continuous and error-free operation of this equipment can be a guarantee of continuous production and non-stop.

The quality of equipment performance is the result of the qualitative integration of the design, procurement and construction stages. Experience in building and recognizing reliable procurement sources along with quality assurance solutions on the one hand and basic knowledge in designing recuperator systems is a guarantee for quality..

We support you in all areas of construction and support related to the equipment of direct recovery industry recuperators

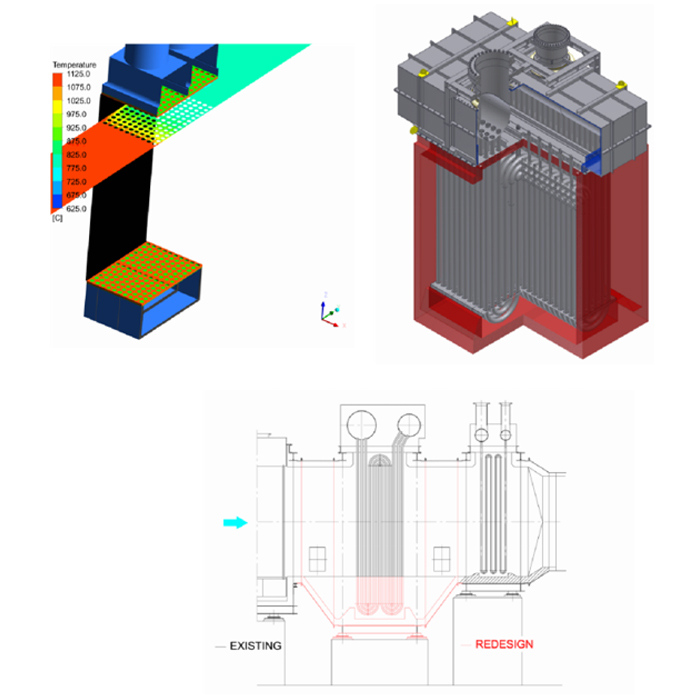

One of the most important advantages of designing a recuperator system in distillery company is up-side down design, which is very effective in shortening the time and cost of installation and repair:

- The recuperator set is placed on a separate structure for easier access

- All air ducts are connected from the bottom of the casing, which makes it much easier to control and repair.

- The installation and removal of the bundles is possible only by opening the duct connections from the upper casing area to minimize the repair time.

The scope of supply of this company in recuperator systems includes the following:

- Combustion air heater

- Feed gas heater

- Process natural gas preheater

- Furnace natural gas and fuel gas Preheater

- Steam generator (HYL, PERED Process)

- Steam superheater (HYLIII Process)

- Top gas heater (HYL III Process)

- Engineering of interconnecting pipes

- Engineering of additional equipment(Process gas mixer, dilution air mixer, ejector stack, etc.)

Basic and detailed engineering of this equipment is performed based on the input information from the process flow in the following order:

- Thermal design

- Mechanical design

- Numeric modeling

- Value engineering

- CFD modeling

Supplementary engineering for the recuperator, including casing and bundle, is done in such a way as to provide complete coverage for all engineering areas, some of which can be mentioned in the following cases:

- Basic and detail engineering of casing

- Basic and detail engineering of refractory

- Detail design of the interconnecting pipework

- Engineering of steel structure

- Engineering of ducts within the battery limit

The services provided by this company in the area of recuperators can be described as follows :

- Engineering Review ( engineering review )

- Improve the thermal levels of the bundles

- Supply of spare bundles with up-to-date engineering

- Upgrade of materials used based on the latest metallurgical developments

- Periodic inspection during the stages of hot and cold stops and control of the health status of the bundles

- Provide documentation for repair and maintenance of the recuperator

- Training of operating personnel for two-way controls and quality supervision