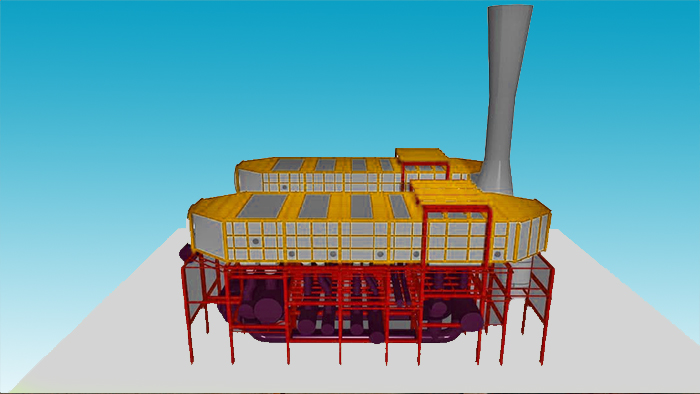

Desulfurization

Desulfurization; Required to increase production

Certainly, with the growth of sponge iron production and development in the extensive exploitation of more mines in the country, the need for desulfurization units has increased more than before in these recovery industries

The company, in cooperation with the Kharazmi Knowledge-Based Company, has formed a specialized consortium to implement desulfurization projects within the EPC framework

Utilizing basic knowledge in basic and detailed design along with high technology and construction capacity and project execution management and record quality of catalyst consumption has created excellent capabilities in providing desulfurization solutions.

Advanced solutions in these projects, while using the maximum Iranian power, have allowed the employer to take advantage of the shortest construction time and the most support.

Sulfur removal solutions can be offered in 3 different ways based on what the employer needs:

- 2+2 vessels parallel line

- 2 vessel +1 back up vessel

- 1 vessel + 1 back up vessel

The scope of construction of desulfurization units in the distillery-Kharazmi consortium is as follows:

- Kharazmi Company :

- Process engineering

- Numerical modeling

- Numerical modeling

- Catalyst loading

- Supervision on commicening

- Distillers Company :

- Mechanical engineering

- Equipment delivery

- On site construction

- QA supervision

Advantages of desulfurization-Kharazmi desulfurization system :

- Minimal process problems during operation

- The most economical implementation cost and cost

- Long service life of desulfurizing adsorbent

- Utilization of control solutions and technologies

- after sales services